Oxidized Bitumen 85-30

What is Oxidized Bitumen 85-30?

Oxidized Bitumen 85-30 is a type of bitumen that has undergone an oxidation process to improve its physical properties, making it more durable and resistant to temperature changes.Bitumen is a viscous, black, semi-solid material that is produced from the distillation of crude oil. It is commonly used in the construction industry for various applications such as road surfacing, waterproofing, and roofing.Oxidized Bitumen 85-30 is produced by blowing air through hot bitumen at a temperature of around 220°C to 260°C. This process increases the bitumen's softening point, penetration value, and viscosity. The resulting product is more resistant to temperature changes, water, and aging, making it ideal for use in hot and tropical climates.

Oxidized Bitumen 85-30 is commonly used in the production of asphalt mixtures, waterproofing membranes, and roofing materials. It is also used as a bonding agent for aggregates and in the manufacturing of adhesives and sealants.

Quality of Oxidized Bitumen 85-30

The quality of Oxidized Bitumen 85-30 is determined by various physical and chemical properties, including its softening point, penetration value, ductility, solubility, and flash point.The following are the typical quality specifications for Oxidized Bitumen 85-30:

Softening point: The softening point of Oxidized Bitumen 85-30 ranges between 80°C to 90°C, which indicates its ability to withstand high temperatures.

Penetration value: The penetration value of Oxidized Bitumen 85-30 is typically between 20 to 30 decimillimeters (dmm), which is an indication of its viscosity or consistency.

Ductility: The ductility of Oxidized Bitumen 85-30 is usually between 5 to 15 centimeters, which shows its ability to elongate or stretch without breaking.

Solubility: The solubility of Oxidized Bitumen 85-30 in trichloroethylene is typically greater than 99%, which indicates its purity and homogeneity.

Flash point: The flash point of Oxidized Bitumen 85-30 is typically greater than 250°C, which is an indication of its safety during storage and transportation.

In addition to these properties, the quality of Oxidized Bitumen 85-30 can also be evaluated based on its durability, resistance to aging and weathering, and compatibility with other materials used in construction.

History of Oxidized Bitumen 85-30

The production of oxidized bitumen dates back to the early 20th century. The process of oxidizing bitumen was developed to improve its physical properties, making it more suitable for various construction applications.In the early days, the process of oxidation was carried out using a blowtorch or a similar heating device, and the bitumen was heated until it became more viscous and thicker. Later on, the process was improved with the development of mechanical blowers that allowed air to be blown through the bitumen at high pressure and temperature, resulting in a more consistent and uniform product.The development of oxidized bitumen 85-30 specifically can be traced back to the mid-20th century, when it was first introduced as a more durable and resistant form of bitumen. It quickly gained popularity in the construction industry, particularly in regions with hot and tropical climates where traditional bitumen was prone to softening and melting.Today, oxidized bitumen 85-30 is widely used in the production of asphalt mixtures, waterproofing membranes, and roofing materials. Its ability to withstand high temperatures and resist aging and weathering has made it an essential component in many construction projects around the world.

Usages of Oxidized Bitumen 85-30

Oxidized Bitumen 85-30 is widely used in the construction industry for various applications due to its excellent durability, weather resistance, and thermal stability. The following are some of the most common usages of Oxidized Bitumen 85-30:

Road construction: Oxidized Bitumen 85-30 is used as a binder in asphalt mixtures for road construction. It improves the stability and durability of the road surface, making it resistant to cracking and deformation.

Roofing: Oxidized Bitumen 85-30 is used as a base material for roofing membranes. It provides excellent waterproofing and weather resistance properties, making it suitable for use in both residential and commercial roofing applications.

Waterproofing: Oxidized Bitumen 85-30 is used as a waterproofing agent for concrete structures, such as bridges, tunnels, and retaining walls. It provides a protective coating that prevents water from penetrating the concrete and causing damage.

Adhesives and sealants: Oxidized Bitumen 85-30 is used as a bonding agent for aggregates in the production of asphalt mixtures. It is also used as an adhesive and sealant in the manufacturing of various construction materials, such as roofing shingles, pipes, and insulation.

Pavement preservation: Oxidized Bitumen 85-30 is used in pavement preservation techniques, such as chip sealing and slurry sealing. It helps to protect the road surface from water damage and other environmental factors, extending the life of the pavement.

Paints and coatings: Oxidized Bitumen 85-30 is used as a component in paints and coatings for steel structures, such as bridges and pipelines. It provides excellent corrosion protection and enhances the overall durability of the coating.

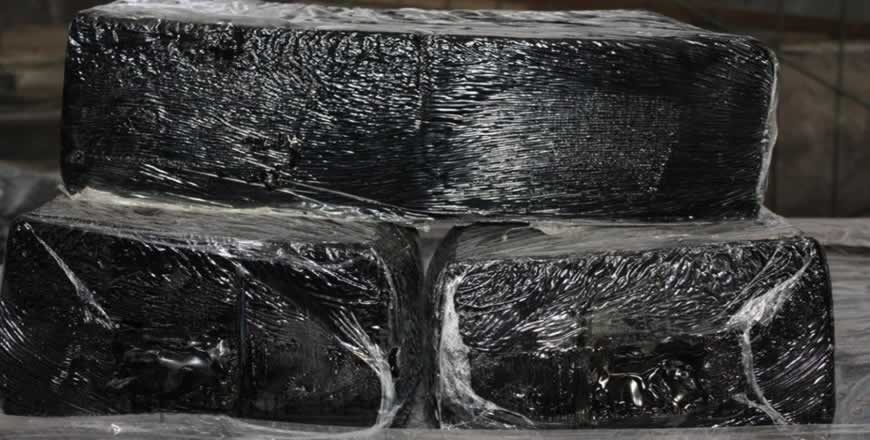

Packing of Oxidized Bitumen 85-30

Oxidized Bitumen 85-30 is typically packed in either steel drums or polybags. The packaging material used depends on the customer's requirements and the mode of transportation.Steel drums are the most commonly used packaging material for Oxidized Bitumen 85-30. The drums have a capacity of 150 kg to 200 kg and are typically coated with an anti-corrosion material to protect the bitumen from moisture and other environmental factors. The drums are then wrapped in plastic sheets to prevent any spillage or leakage during transportation.

Polybags are another packaging option for Oxidized Bitumen 85-30. The bags have a capacity of 25 kg to 50 kg and are made of high-density polyethylene (HDPE) or polypropylene (PP) material. The bags are typically palletized and wrapped in plastic sheets to ensure their safe transportation and storage.In addition to steel drums and polybags, Oxidized Bitumen 85-30 can also be transported in bulk using tankers or containers. Bulk transportation is usually used for larger quantities of bitumen, and the tanks or containers are equipped with heating systems to maintain the bitumen's temperature during transportation.

Prices Oxidized Bitumen 85-30

The price of Oxidized Bitumen 85-30 can vary depending on several factors, such as the market demand, production costs, and transportation costs. It is also influenced by the grade, quality, and quantity of the bitumen purchased.

As of my knowledge cutoff date of September 2021, the price of Oxidized Bitumen 85-30 in the international market was around USD 600-900 per metric ton (MT). However, it is important to note that prices can fluctuate over time and can be affected by various factors, such as changes in oil prices, currency exchange rates, and supply and demand dynamics.It is recommended to consult with local suppliers or manufacturers for up-to-date pricing information on Oxidized Bitumen 85-30 in your region, as prices can vary based on location and market conditions.

Delivery time and Readiness of Oxidized Bitumen 85-30

The delivery time of Oxidized Bitumen 85-30 can vary depending on several factors such as the location of the supplier or manufacturer, the transportation method, and the quantity ordered. Typically, the delivery time can range from a few days to several weeks, depending on these factors.

If the bitumen is readily available in stock, the delivery time can be faster. However, if the supplier needs to produce or import the bitumen, the delivery time may be longer. Additionally, the transportation method chosen can also affect the delivery time. For example, shipping by sea may take longer than shipping by air or land.

It is important to note that the readiness of Oxidized Bitumen 85-30 may also depend on the specific grade and quality required by the customer. If a particular grade or quality of bitumen is not readily available, the supplier may need to produce or customize the bitumen to meet the customer's requirements, which may result in a longer delivery time.

Analysis Table of Oxidized Bitumen 85-30

Here is an analysis table for Oxidized Bitumen 85-30:

| Parameter |

Typical Value |

| Softening Point (°C) | 80-90 |

| Penetration at 25°C (dmm) | 10-20 |

| Ductility at 25°C (cm) | > 5 |

| Solubility in CS2 (%) | > 99 |

| Loss on Heating (%) | < 0.2 |

| Drop in Penetration (%) | < 20 |

| Flash Point (°C) | > 250 |

| Solubility in Toluene (%) | > 99 |

| Density at 25°C (kg/m³) | 1.01-1.05 |

| Organic Matter Content (%) | > 99 |

| Water Content (%) | < 0.2 |

| Ash Content (%) | < 0.5 |

| Spot Test | Negative (no bleeding or oil) |