Oxidized Bitumen 85-40

What is Oxidized Bitumen 85-40?

Oxidized Bitumen 85-40 is a type of bitumen that has undergone an oxidation process to increase its softening point and durability. It is commonly used in a variety of construction and industrial applications, including roofing, waterproofing, pipe coating, and pavement maintenance.During the oxidation process, air is blown through hot bitumen under controlled conditions, which causes the bitumen to become more viscous and increases its softening point. This results in a bitumen with improved resistance to temperature fluctuations, water, and chemical damage.

The number "85-40" in the name refers to the softening point and penetration grade of the oxidized bitumen. The softening point is the temperature at which the bitumen softens and begins to flow under a specified load, while the penetration grade refers to the depth in tenths of a millimeter that a standard needle penetrates into the bitumen sample at a standard temperature and time.

Quality of Oxidized Bitumen 85-40

The quality of Oxidized Bitumen 85-40 depends on several factors, including the raw material used, the manufacturing process, and the storage and handling conditions. Generally, high-quality Oxidized Bitumen 85-40 will have the following characteristics:

Softening point: The softening point of Oxidized Bitumen 85-40 should be between 80 and 90 degrees Celsius, indicating that it has good resistance to high temperatures.

Penetration: The penetration value of Oxidized Bitumen 85-40 should be between 35 and 45 dmm, indicating that it has good hardness and viscosity.

Ductility: The ductility of Oxidized Bitumen 85-40 should be at least 100 cm, indicating that it has good flexibility and can withstand deformation without breaking.

Solubility: The solubility of Oxidized Bitumen 85-40 should be low, indicating that it has good resistance to water and moisture.

Durability: Oxidized Bitumen 85-40 should have a long service life and maintain its properties over time, even under harsh environmental conditions.

In addition to these properties, high-quality Oxidized Bitumen 85-40 should also be free from impurities, such as dust, water, and other contaminants, which can affect its performance and durability. It is important to ensure that the material is stored and handled properly to maintain its quality and prevent degradation.

History of Oxidized Bitumen 85-40

The use of bitumen as a waterproofing material dates back thousands of years, with evidence of its use in ancient civilizations such as the Mesopotamians, Egyptians, and Persians. However, the process of oxidizing bitumen to improve its properties is a more recent development.The first patent for the process of oxidizing bitumen was filed by Walter C. DeGroot in 1927. DeGroot's process involved blowing air through hot bitumen under controlled conditions, which resulted in a bitumen with improved resistance to temperature fluctuations, water, and chemical damage. This process was initially used to produce industrial bitumens for road construction and other applications.

In the 1950s, the use of oxidized bitumen as a roofing material became more widespread, particularly in the United States. The increased demand for durable and weather-resistant roofing materials led to the development of new grades of oxidized bitumen, such as Oxidized Bitumen 85-40, which had a higher softening point and improved performance in hot climates.

Usages of Oxidized Bitumen 85-40

Oxidized Bitumen 85-40 is a popular material in the construction industry due to its excellent waterproofing and weatherproofing properties. Some common usages of Oxidized Bitumen 85-40 include:

Roofing: Oxidized Bitumen 85-40 is often used as a roofing material due to its ability to resist water, weathering, and UV radiation. It is commonly used in built-up roofing systems, as well as modified bitumen roofing systems.

Waterproofing: Oxidized Bitumen 85-40 is also used as a waterproofing material for foundations, basements, and other below-grade structures. It provides an effective barrier against water intrusion and helps to protect the structure from damage.

Pavement maintenance: Oxidized Bitumen 85-40 is commonly used for pavement maintenance and repair, particularly in hot climates. It is used to seal cracks and joints in asphalt and concrete pavements, as well as to coat and protect the surface from weathering and oxidation.

Pipe coating: Oxidized Bitumen 85-40 is used as a coating material for steel and concrete pipes to protect them from corrosion and other forms of damage.

Adhesives: Oxidized Bitumen 85-40 is used as an adhesive in a variety of applications, such as bonding insulation materials to roofing substrates, and as a bonding agent for asphalt paving.

Packing of Oxidized Bitumen 85-40

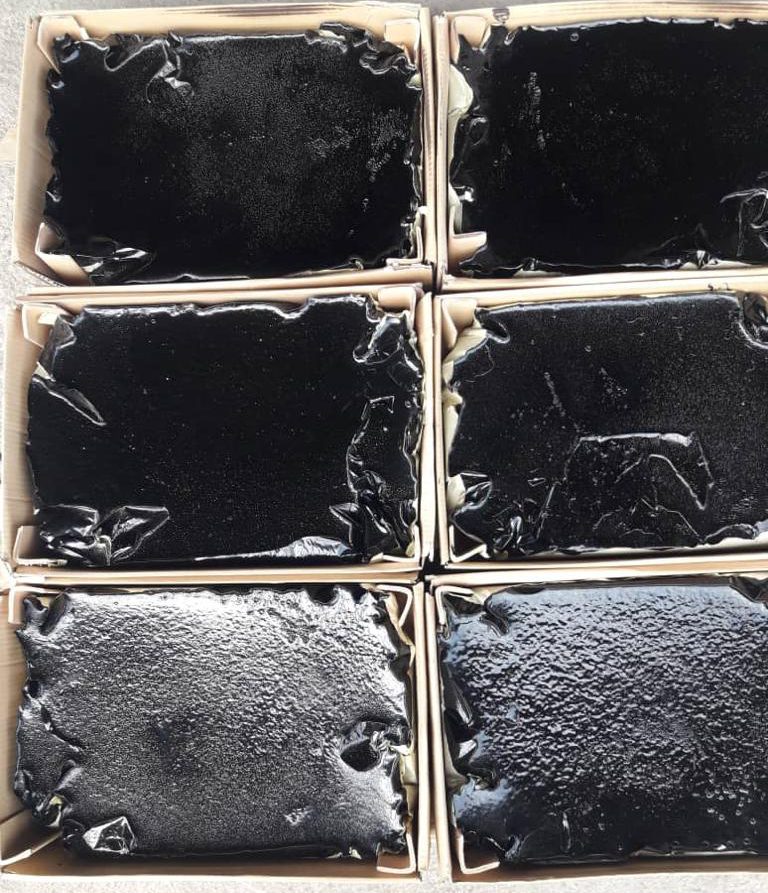

Oxidized Bitumen 85-40 is typically packed in a variety of packages, depending on the quantity required and the needs of the customer. The most common types of packaging for Oxidized Bitumen 85-40 include:

Meltable Bags: This is the most common packaging for Oxidized Bitumen 85-40. The material is packed in polyethylene bags, which are then placed in a carton box. The bags can be melted easily by heating, and the bitumen can be poured directly from the bag.

Steel Drums: Oxidized Bitumen 85-40 can also be packed in steel drums of various sizes, ranging from 150 kg to 200 kg. The drums are lined with a layer of polyethylene or similar material to prevent leakage.

Bulk Shipment: For large quantities, Oxidized Bitumen 85-40 can be shipped in bulk by tanker trucks or rail cars. In this case, the bitumen is loaded directly into the tanker or rail car.

Regardless of the packaging used, it is important to ensure that the material is handled and stored properly to prevent damage or degradation. The packaging should be kept in a cool, dry place away from direct sunlight, heat sources, and moisture. It is also important to follow proper safety procedures when handling and transporting Oxidized Bitumen 85-40, as it can be a hazardous material if not handled properly.

Prices Oxidized Bitumen 85-40

The price of Oxidized Bitumen 85-40 can vary depending on several factors such as the supplier, location, and quantity ordered. Additionally, market conditions and demand can also impact the price of the material. As an AI language model, I don't have access to real-time market data, so the following information should be taken as an estimate.

Generally, the price of Oxidized Bitumen 85-40 ranges from $400 to $700 USD per metric ton. However, prices may be higher or lower depending on the aforementioned factors. Additionally, suppliers may offer discounts for large orders or long-term contracts.It is important to note that the price of Oxidized Bitumen 85-40 is only one factor to consider when choosing a supplier. Other factors such as product quality, delivery time, and customer service should also be taken into account to ensure that you are getting the best value for your investment.

Delivery time and Readiness of Oxidized Bitumen 85-40

As an AI language model, I don't have access to real-time information about the availability and delivery time of Oxidized Bitumen 85-40. However, delivery times can depend on several factors such as the location of the supplier, the quantity ordered, and the shipping method chosen.

In terms of readiness, Oxidized Bitumen 85-40 is typically readily available from suppliers who specialize in the production and distribution of bitumen products. This grade of bitumen is one of the most commonly produced and used grades of oxidized bitumen.

When placing an order for Oxidized Bitumen 85-40, it is important to discuss delivery times with the supplier to ensure that the material will be delivered when needed. Additionally, it may be possible to expedite delivery by paying a premium for express shipping or by working with a supplier that has a local distribution network.

Analysis Table of Oxidized Bitumen 85-40

| Property | Test Method | Specification |

| Softening point (°C) | ASTM D36 | 80-90 |

| Penetration at 25°C (0.1 mm) | ASTM D5 | 35-45 |

| Ductility at 25°C (cm) | ASTM D113 | > 100 |

| Solubility in trichloroethylene (%) | ASTM D2042 | > 99 |

| Loss on heating, 5 hours at 163°C (%) | ASTM D6 | < 0.5 |

| Flash point (°C) | ASTM D92 | > 225 |

| Specific gravity at 25°C/25°C | ASTM D70 | 1.00-1.05 |